Written by: Melissa Lopez and Surabhi Khanderia

In a recent groundbreaking development, the announcement of CalGreen’s mandatory implementation of life cycle assessments for all buildings surpassing 50,000 square feet, effective from 2024, has sent ripples of anticipation throughout the sustainability realm. Concurrently, the advent of AB 2446 has further heightened the urgency, as it compels the California Air Resources Board (CARB) to institute comprehensive embodied carbon regulations, slated to be phased in as early as next year. In light of these momentous regulatory shifts, it is imperative for projects to proactively embrace the preservation of existing structures and seamlessly integrate life cycle assessments of materials into their design processes.

In the not-too-distant past, Leading Edge seized an extraordinary opportunity to collaborate with the esteemed clients of Howard CDM and Studio One Eleven. Our concerted efforts were dedicated to propelling the pursuit of WELL certification for the The Exchange at Bellflower—an endeavor exemplifying remarkable excellence. It brings us great delight to underscore the team’s accomplishment of securing three points within the life cycle assessment credit, achieved through the masterful repurposing of the pre-existing structure. This study was conducted with a singular objective in mind: to thoroughly comprehend the embodied carbon savings yielded by this project.

Howard CDM purchased a 70-year-old building that was a JC Penney retail store from 1951 to 1980 and transformed it from what was considered an eyesore into a mixed-use building dubbed The Exchange Bellflower. The purpose of this study is to quantify the embodied carbon avoided and waste reduction as a result of the salvaging and repositioning the building.

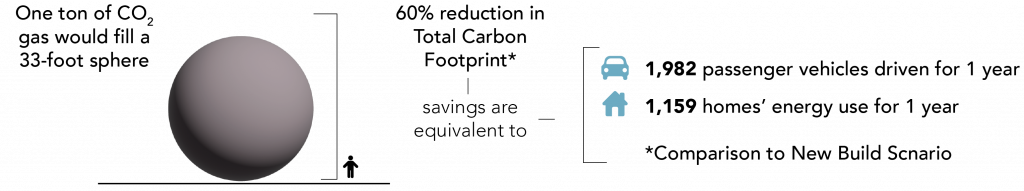

The A1-A3 & C1 Life Cycle Assessment quantifies the Global Warming Potential (GWP) avoided by reusing many of the existing elements. Repurposing avoided nearly 60% of embodied carbon when compared to a 100% new build scenario.

Global Warming Potential

Understanding the GWP of development projects is essential to avoiding the emissions associated with embodied carbon, and thereby drastically reduces the environmental impact contributing to climate change. The materials considered in this project release different types of Greenhouse Gases (GHG), so GWP is the common metric to communicate these various totals.

EXISTING STRUCTURE

CURTAIN WALLS

WALLS

CEILING

DOORS

FLOORS

ROOF

EXISTING STRUCTURE

NEW CONSTRUCTION

Lifecycle Review Analysis

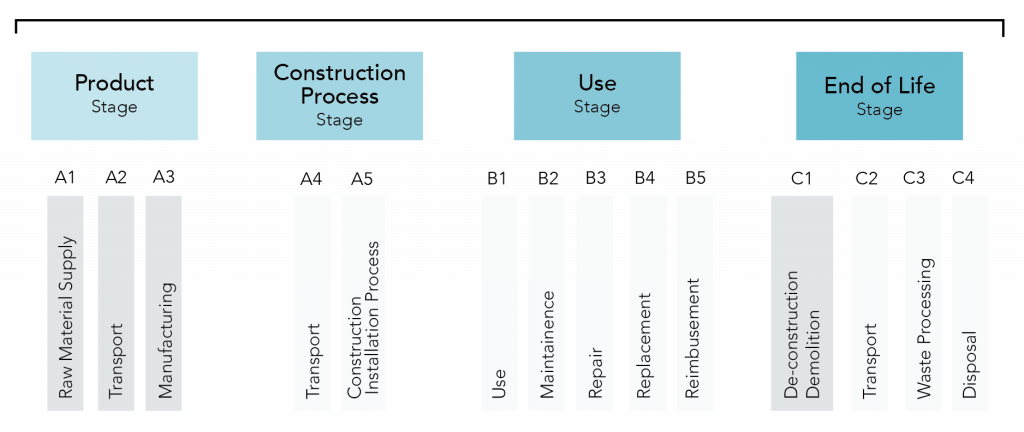

A thorough LCA study includes several stages starting with source extraction through the end of the material’s lifecycle when it is either recycled or sent to the landfill.

Scope of Analysis

This study accounts for the first three stages (A1 – A3) of a typical LCA which includes the emissions as a result of the extraction of raw materials, transportation emissions to the manufacturing plant, and the emissions released during the manufacturing process.

The C1 scope took into account GWP associated with transport, materials, products, related energy and water use of the demolition phase.

This project considers the structural and interior elements including foundations, floors, ceilings, walls, windows and doors. This excludes furnishing, MEP systems, and finishes.

Demolition waste can have a significant impact on a construction project’s carbon footprint. An effective way to reduce demolition waste is to reuse existing structure for the new building.

The Exchange focused on preserving many elements of the existing structure including brick walls, concrete columns, slabs, etc. This resulted in a reduction of nearly 8 million pounds of demolition waste. In terms of carbon, this strategy cut carbon emissions associated with demolition waste by 64%. Additionally, of the existing elements that were demolished, 65% were recycled. This further reduced the total tonnage of waste that was sent to the landfill.

Data Acquisition for Materials

Material quantities are pulled from the Revit Model and architectural drawings provided by Studio One Eleven. The Building Transparency carbon calculator tool, EC3, helps to define the carbon equivalence for materials used.

Assumptions

Note the carbon emissions associated with materials and demolition are industry averages and were not derived from exact manufacturer data.

Recycling rates were based on the minimum 65% diversion of non-hazardous C&D waste required by the CalGreen standards.