PART II: PVC Alternatives

Polyvinyl Chloride (PVC) is one of the most widely used plastics in the building industry, praised for its low cost and durability—but increasingly scrutinized for its environmental and health impacts. As the demand for healthier, more sustainable materials grows, designers and builders are reevaluating their reliance on PVC across key applications. This article compares alternative materials to PVC in four major use cases—siding, window frames, flooring, and piping—by analyzing their performance, embodied carbon, toxicity, and long-term viability in construction.

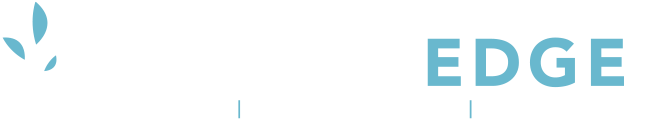

Siding

Vinyl (PVC) Siding

Embodied Carbon

~9–10 kg CO2e/m² 1(moderate)

Lifespan and Maintenance

~50 yr life; minimal maintenance (no painting)

Recyclability/ EOL

Technically recyclable, but post-use recycling is limited. Landfill stable; incineration can form dioxins.

Other Environmental Impacts

Made from fossil feedstocks & chlorine – toxic production emissions (e.g. dioxins, vinyl chloride). No off-gassing in use, but hazardous if burned

Fiber-Cement Siding

Lifespan and Maintenance

~50 yr life; requires painting/sealing every ~5–10 yrs to prevent moisture damage.

Recyclability/ EOL

Not recycled; treated as construction debris (landfilled). Inert at EOL.

Other Environmental Impacts

Cement production = high CO2. No toxic emissions in use; silica dust from cutting is a worker hazard. No off-gassing; non-combustible (good fire performance).

Wood Siding (Cedar, etc)

Embodied Carbon

Low embodied carbon (manufacturing ~2–5 kg CO2e/m²)

Recyclability/ EOL

Biodegradable/combustible. Can be burned for energy or left to decompose (releases stored CO2). Renewable resource; scraps can be recycled into mulch or composite wood.

Other Environmental Impacts

Low-toxicity natural material. Sustainably harvested wood stores CO2. Requires paints/preservatives (choose low-VOC to avoid emissions). Much lower overall environmental impact than synthetics.

Metal Siding (Cedar, etc)

Embodied Carbon

Moderate-high (steel ~15; aluminum ~18 kg CO2e/m²) 4;

; high initial energy, but can be offset by recycling.

Lifespan and Maintenance

50+ yr life (very durable). Factory coatings prevent rust; may need repainting if coating fails (20+ year finish life typical).

Recyclability/ EOL

100% recyclable; high scrap value encourages recycling; Often >25% recycled content in new panels. Landfill if not recycled, but doesn’t leach toxins.

Other Environmental Impacts

No on-site emissions. Mining/refining impacts (bauxite or iron ore extraction). Aluminum production is energy-intensive (climate impact can drop ~80% if recycled vs. virgin). Both metals are non-combustible and contain no persistent toxins (aside from finish coatings that may use PFAS in some cases).

Resources:

- https://polymericexteriors.org/wp-content/uploads/2022/06/VSI-EPD-VinylSiding-2022.pdf#:~:text=GWP%20Global%20Warming%20Potential%20kg,13%200.00E%2B00

- https://api.environdec.com/api/v1/epdlibrary/files/8168b86f-ab27-4bd3-16f7-08dbca69748b/data#:~:text=Reference%20Service%20Life%20,by%20James%20Hardie%20for%20CY20

- https://cms.realcedar.com/wp-content/uploads/2014/05/Real_Cedar-EPD-Cedar_Siding-2016_11_08.pdf#:~:text=Global%20warming%20potential%20,06

- https://www.metalconstruction.org/view/download.php/online-education/education-materials/edp-educational-files/epd-for-formed-metal-sheets#:~:text=

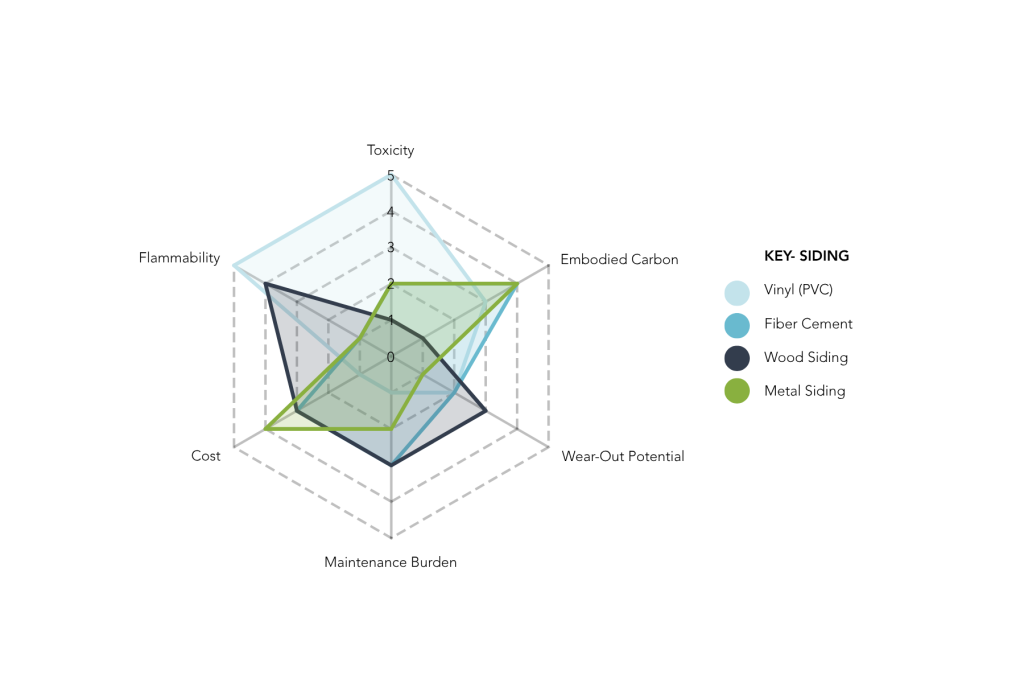

Window Frame

Wood frames generally have the lowest embodied carbon (wood is renewable and stores carbon), while metal frames (especially aluminum) have the highest. using 80% recycled aluminum can cut climate impact ~20%. Modern vinyl (PVC) frames, fiberglass frames, and aluminum-clad wood frames tend to be in a similar emissions range (cradle-to-gate), and differences in manufacturing impacts are smaller than the impacts of frame longevity.

Fiberglass or wood-clad aluminum composite materials are preferable over PVC from a health and equivalent energy performance perspective. In theory, PVC has more recycling potential but in reality, it doesn’t get recycled. With that in mind, it is better to prefer other materials such as fiberglass.

If vinyl is preferred, ensure the specification of metal-reinforced vinyl for fire hardening.

Vinyl (PVC) Siding

Recyclability/ EOL

Technically recyclable PVC, but most end up landfilled. Incineration can create dioxins. Little recycled content currently in frames.

Other Environmental Impacts

Avoiding PVC eliminates: chlorine-related toxins. PVC production releases dioxins; vinyl frames can contain stabilizers/plasticizers (older products had lead, phthalates). Newer vinyl windows are phthalate-free, but legacy toxicity and end-of-life pollution remain concerns.

Aluminum Frame

Embodied Carbon

High if virgin (~60–100 kg CO2e per window); can be lower with recycled aluminum (e.g. ~20–30% less with 40% recycled content)2

Lifespan and Maintenance

50+ yrs (does not rot; very robust). Needs thermal break for energy efficiency. Excellent structural strength (good for large spans).

Recyclability/ EOL

Highly recyclable – scrap aluminum is routinely recycled, greatly reducing lifecycle impact.

Other Environmental Impacts

No VOC/off-gas. Upstream impact from mining & smelting (electricity-intensive). No chlorine or persistent toxins. Thermal break strips (plastic) are a small % of frame.

Fire-resistant. Overall, highest embodied energy but clean end-of-life.

Wood Frame

Embodied Carbon

Low (~30–50% lower CO2e than vinyl/aluminum) Wood itself may even store more CO2 than emitted in processing, yielding a small net GWP.3

Lifespan and Maintenance

30–50 yrs (can be longer if protected). Needs repainting or sealing to prevent rot. Good insulator. Less dimensionally stable than others (can warp if wet).

Recyclability/ EOL

Reusable (old wood windows can sometimes be refurbished). At EOL, wood can be burned for energy or composted – minimal residual waste.

Other Environmental Impacts

Ensure sustainably harvested wood. Usually factory-treated with preservatives and painted – use low-toxicity options. No significant indoor emissions. Combustible (lower fire resistance).

Fiberglass Frame

Embodied Carbon

Moderate (~50–70 kg CO2e per window, similar or slightly less than vinyl). Uses less plastic by mass than vinyl, but epoxy/polyurethane resins are petro-based.4

Recyclability/ EOL

Not commonly recycled (thermoset composite can’t be remelted). Likely landfill at EOL (inert).

Other Environmental Impacts

PVC-free (made of glass fibers + polymer). No known indoor emissions. Production involves epoxy or polyurethane – potential occupational hazards, but final product is inert.

Composite Frame

Embodied Carbon

Moderate (in range of vinyl/fiberglass). Wood-plastic composites can lower fossil carbon content vs all-PV4

Lifespan and Maintenance

30–40 yrs (depending on mix; often similar to vinyl). Many are basically wood interior with either vinyl or fiberglass exterior.

Recyclability/ EOL

Depends on type: Wood-Aluminum composites: aluminum outer cladding can be recycled, wood interior handled as wood. Wood-PVC composites: not recycled because inseparable materials.

Other Environmental Impacts

Varies: e.g. Aluminum-clad wood gives benefits of wood (low carbon) with aluminum durability – but small PVC/foam thermal breaks may still exist. Fiberglass-wood composites avoid PVC entirely. Wood-PVC composites (some “vinyl composite” windows) still entail PVC, albeit with some bio-content. Check specific composite makeup to judge toxicity – e.g. some use PVC cladding (undesirable for a PVC-free goal)

Resources:

- https://www.envirology.co.nz/a-review-of-life-cycle-assessment-of-windows/#:~:text=justification%20of%20increased%20manufacturing%20effects,during%20manufacturing%20to%20achieve%20improved

- https://solutions.covestro.com/-/media/covestro/corporate/productsafetyfirst/region-specific-services/usa/life-cycle-assessment/gthurm-flyer.pdf?rev=4adae9e5bb5d4933990df914a8939c2a&hash=B51E782276D933FA179D9EE445AB1A1E#:~:text=energy%20and%20impacts%20,even

- https://www.envirology.co.nz/a-review-of-life-cycle-assessment-of-windows/#:~:text=justification%20of%20increased%20manufacturing%20effects,during%20manufacturing%20to%20achieve%20improved

- https://www.sustain.ubc.ca/sites/default/files/2022-018_Research%20on%20the%20impacts%20of%20Innovative%20Fenestration%20Materials_Zargar.pdf#:~:text=Window%20frames%20can%20be%20made,2

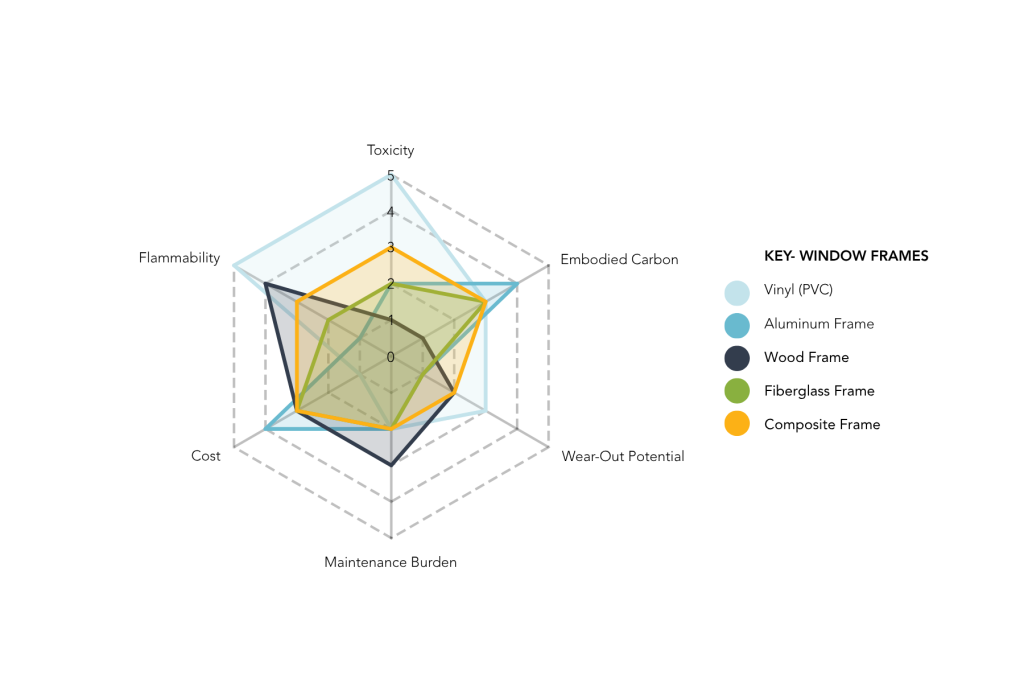

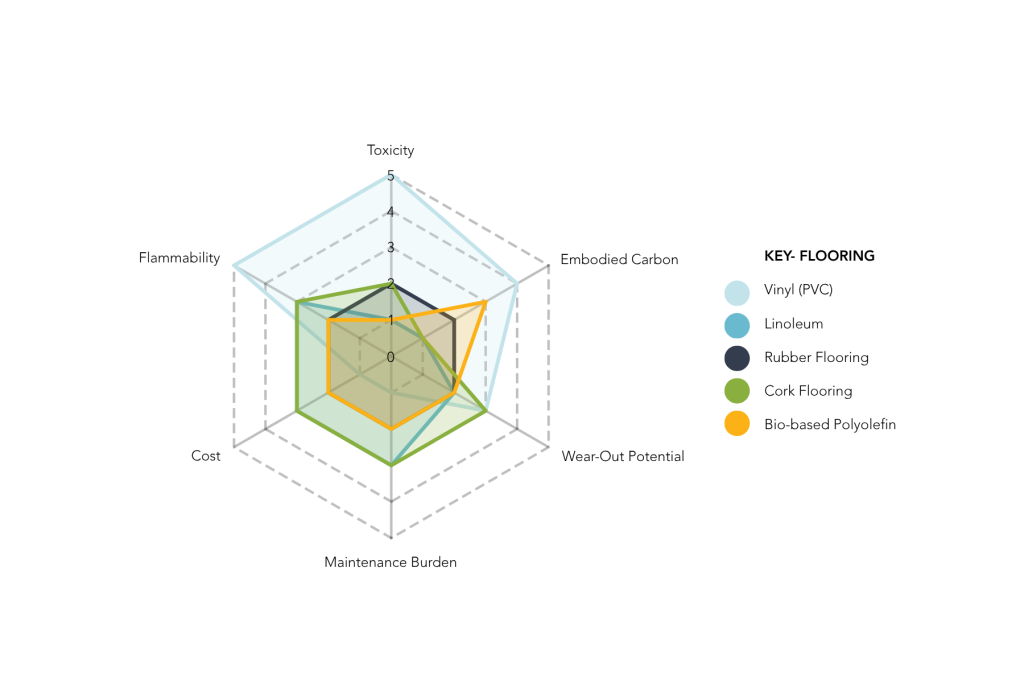

Flooring

Linoleum and Cork resilient flooring materials are clear red-list free winners in the conversation of embodied carbon and health. The drawback could be on the cost side for material and installation. This is still competitive with the Luxury Vinyl flooring (LVT). Long-term replacement costs are also lower due to durability.

Vinyl Flooring (PVC sheet, LVT)

Embodied Carbon

Moderate-High: Typically ~5–8 kg CO2e/m² (petrochemical PVC + calcium carbonate filler) – highest among these options.

Lifespan and Maintenance

~15–20 years in heavy use (highly water and wear resistant, but not refinishable).

Recyclability/ EOL

Not recycled (disposed in landfill or incineration). Landfill: persists for centuries. Incineration: releases HCl, dioxins, heavy-metal stabilizers into environment.

Other Environmental Impacts

Contains PVC: made with chlorine and often phthalates – can off-gas plasticizers and emit VOCs into indoor air. Production and disposal generate toxic pollutants. On the plus side, it’s cheap, durable, and low-maintenance (no waxing needed for some LVT). However, many organizations now push to avoid vinyl for health reasons

Linoleum (natural linseed-based)

Embodied Carbon

Very Low: ~0 kg CO2e/m² (carbon-neutral cradle-to-gate; ~1–2 kg CO2e including full life). Manufacturing actually sequesters a bit of CO2.

Recyclability/ EOL

Biodegradable: can be landfilled or even composted – breaks down into organic matter. No toxic legacy.

Other Environmental Impacts

100% bio-based (linseed oil, wood flour, jute backing). No chlorine, no phthalates, no VOCs – very healthy. Mild linseed odor when new. Naturally bacteriostatic. Needs periodic waxing for shine, but newer linoleum has durable factory finishes. Widely considered a sustainable flooring choice with minimal environmental impact

Rubber Flooring (natural or synthetic rubber)

Embodied Carbon

Low: Depends on formulation – natural rubber tiles can be carbon-neutral (the rubber comes from tree latex); mixed rubber ~1–3 kg CO2e/m². Generally lower than PVC.

Recyclability/ EOL

Partially recyclable – often made with recycled content. End of life: can be recycled in ground form for mats, or incinerated for energy (no chlorine emissions).

Other Environmental Impacts

If natural rubber: renewable resource (from rubber trees). No halogens or plasticizers. May have some odor (from sulfur curing agents) initially, but low VOC emission certified products are available. Does not foster microbial growth. Overall, healthier indoor profile than vinyl.

Cork Flooring (cork tiles/planks)

Embodied Carbon

Very Low: Production is low-energy and cork oak absorbs CO2 – net GWP often <2 kg/m

Lifespan and Maintenance

~20 yrs (soft underfoot; the compressibility can show wear in heavy traffic). Surface can be re-coated to extend life.

Recyclability/ EOL

Biodegradable/renewable: cork can be recycled or will decompose in landfill without toxins.

Other Environmental Impacts

Made from cork oak bark (no tree cut down). Binders/finishes are typically polyurethane – choose low-VOC finishes. No significant emissions once cured. Provides a cushioned, warm floor with natural thermal/acoustic insulation. Avoids all PVC-related concerns.

Bio-based "“Polyolefin” Flooring (PVC-free sheet)

Embodied Carbon

Moderate-Low: ~3–5 kg CO2e/m² (petroleum-derived but chlorine-free; some brands incorporate bio-content).

Lifespan and Maintenance

15–25 yrs (similar performance to vinyl sheet in wear and moisture).

Recyclability/ EOL

Not commonly recycled (thermoplastic polyolefins could be theoretically melted down, but post-use recycling is rare). Safer to incinerate than PVC (no dioxin).

Other Environmental Impacts

Typically made from polypropylene or polyethylene with mineral fillers – no chlorine, no phthalates. Much less toxic profile; certified low emissions. Marketed as “PVC-free” vinyl alternatives. Slightly higher embodied carbon than linoleum, but far fewer health hazards. Good choice where a sheet flooring is needed without PVC.

Resources:

- https://www.homeadvisor.com/cost/flooring/install-vinyl-flooring/

- https://www.homeadvisor.com/cost/flooring/install-linoleum-flooring/

- https://www.homeadvisor.com/cost/flooring/install-cork-flooring/

- https://www.fixr.com/comparisons/linoleum-vs-vinyl-flooring

- https://www.fixr.com/comparisons/cork-flooring-vs-vinyl-flooring

- https://www.flooringstores.com/blog/linoleum-flooring/

- https://www.flooringstores.com/blog/cork-flooring/

- https://www.forbo.com/flooring/en-us/

- https://www.forbo.com/flooring/en-us/segments/education/why-marmoleum/pfkr93

- https://www.rsmeans.com/

- https://www.forbo.com/flooring/en-us

- https://www.greenbuildingadvisor.com

- https://www.builditgreen.org

- https://healthybuilding.net

- https://www.ec3.eco

- https://spot.ul.com

- https://nsf.org

- https://declare.living-future.org/

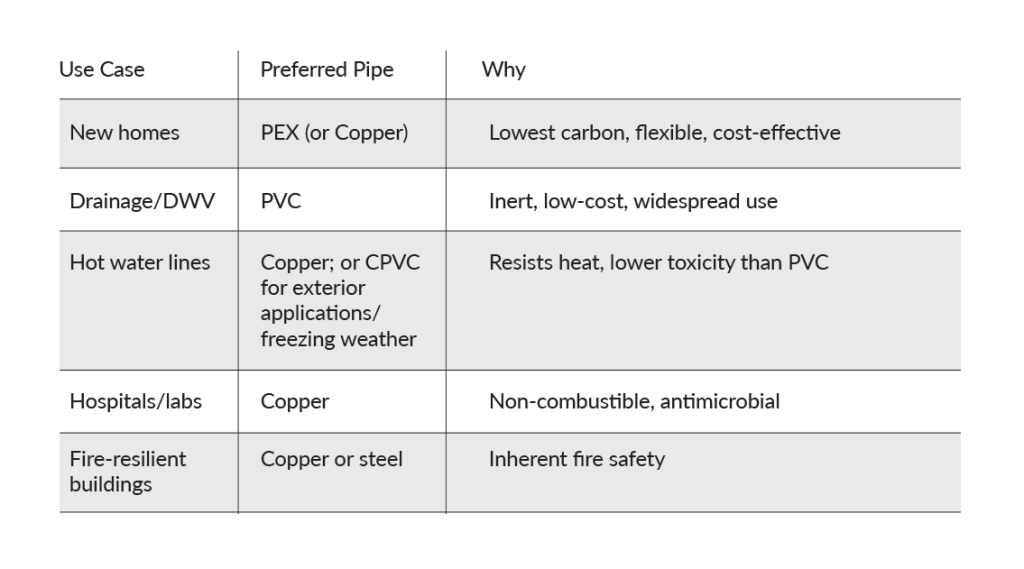

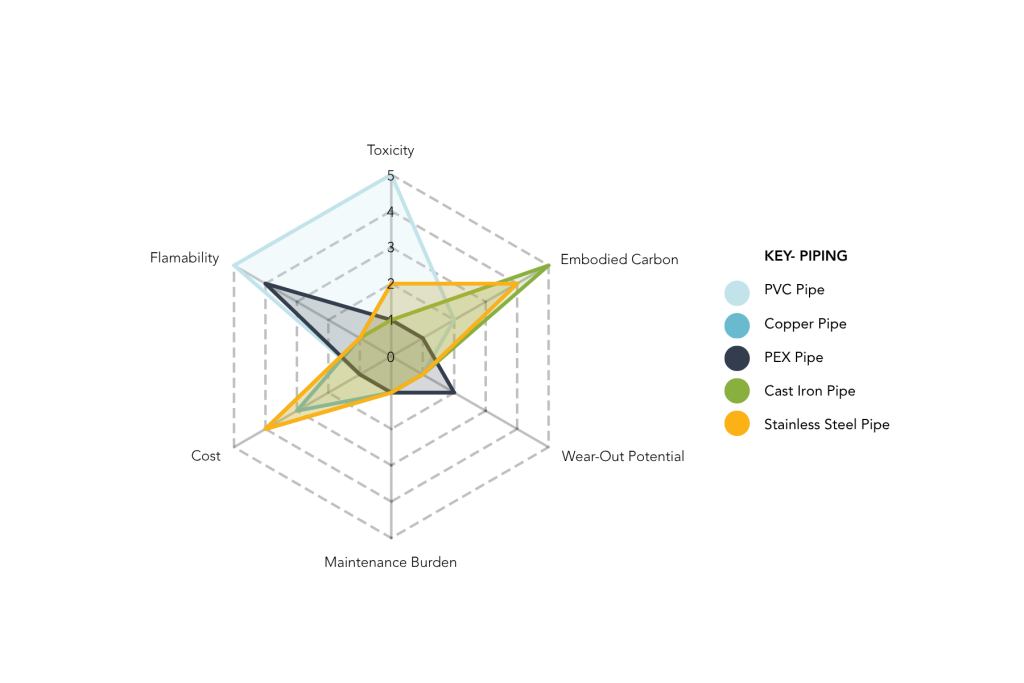

Piping

While PEX stands out from an environmental and health perspective, and CPVC & copper pipes are preferred for hot water temperatures, however, copper cannot withstand freezing temperatures, since metal pipes can burst in freezing temperature and PEX is not great with external exposure.

Embodied carbon spent for copper piping seems worth, given that it leached copper only to safe levels, is usually recycled and has antimicrobial properties.

One may consider the following application:

PVC Pipe

Embodied Carbon

Low – e.g. ~2–3 kg CO2e per ¾″-1″ diameter pipe (significantly less than metals) ~0.5–0.75 kg CO₂e/m

Lifespan and Maintenance

50+ years (in cool, dark conditions). Used for cold water and DWV (drains, waste, vent). CPVC (chlorinated PVC) used for hot water.

Recyclability/ EOL

Limited recycling (most end up landfilled). Landfill-stable. If burned, releases HCl and dioxins – require careful incineration controls

Other Environmental Impacts

Manufacture involves toxic chemicals (vinyl chloride, dioxins) – PVC is flagged as a “high hazard” material. In use, generally inert (no rust or corrosion). No nutrient for bacteria. May leach minor vinyl additives. Burning PVC in fires creates corrosive, toxic smoke.

Copper Pipe

Embodied Carbon

High – on the order of ~1.5–3 kg CO2e per kg; ~2–4 kg CO2e per meter for typical sizes (copper/steel pipes have ~7–11× PVC’s impact)

~1.5–2.4 kg CO₂e/m

Lifespan and Maintenance

50–100 yr lifespan (doesn’t degrade if water chemistry is neutral). Used for hot/cold water in many homes. Tolerates high heat and pressure.

Recyclability/ EOL

Fully recyclable – high scrap value means copper is usually reclaimed. Recycling drastically cuts its lifecycle energy.

Other Environmental Impacts

Mining impacts: copper extraction is energy-intensive and can pollute (though recycling copper avoids mining). No chemical off-gassing; can leach copper into water (can stain fixtures, upset fish if aquarium). Naturally antimicrobial interior. Metal pipes can burst if water freezes. Non-combustible and no toxic gases in fire.

PEX Pipe

Embodied Carbon

Very Low – uses less material and less energy than PVC or metals. One study: switching copper to PEX cut GWP by 42%. (~0.5 kg CO2e or less per meter) ~0.3–0.5 kg CO₂e/m

Recyclability/ EOL

Not recycled (thermoset plastic). Disposed in landfill or waste-to-energy incineration (where it mainly yields CO2/H2O upon full combustion).

Other Environmental Impacts

No chlorine or heavy metals – made from petroleum like common plastics. Can cause temporary “plastic” taste in water, but generally safe (NSF certified). Doesn’t corrode or scale. Lower burst risk in freezing (it’s somewhat elastic). In a fire, will burn/melt away, but combustion byproducts are less toxic than PVC’s. Overall a less toxic alternative to PVC for water pipes with the smallest carbon footprint among pipe options.

Cast Iron Pipe

Embodied Carbon

Very High – extremely heavy; overall impacts ~8–10× that of PVC for drains. (E.g. a 4″ cast iron soil pipe ~20 kg/m vs 4″ PVC ~2 kg/m – and per kg iron CO2 is not low.)

Lifespan and Maintenance

80–100 yr life in drainage (robust against wear). Used for sewer/waste stacks; also as fire-safe, quiet alternative to PVC

Recyclability/ EOL

Recyclable – often made with recycled scrap and can be recycled again. If landfilled, will slowly rust back to iron oxides.

Other Environmental Impacts

No chemical emissions (inert iron). Very fire resistant. Much heavier (more transport energy and labor). No microbial growth issues. Can corrode internally over decades (from certain wastewater acidity) but generally thick-walled. Often used in green building despite carbon cost, for its durability and avoidance of plastics.

Stainless Steel Pipe

Embodied Carbon

High – less mass than cast iron but stainless steel production has high CO2 per kg (nickel, chromium refining). Impacts per meter closer to copper’s range (several times PVC).

Lifespan and Maintenance

50+ yr life. Used in commercial/plenum applications, or where water purity and strength are needed. Handles very high temperatures/pressures

Recyclability/ EOL

Recyclable (metals loop). Often reused in industrial scrap.

Other Environmental Impacts

Durable and inert (stainless won’t leach noticeable metals into water under normal conditions). Expensive, so not used in most dwellings. Like other metals, no in-use emissions and no fire emissions.

Resources:

- https://www.teppfa.eu/

- https://www.plasticseurope.org

- https://www.ablesci.com/scholar/paper?id=rnmDZ2Nx8#:~:text=consumption%20of%20PVC,the%20design%20of%20building%20pipes

- https://www.greenbuildingsupply.com/Learning-Center/Flooring-LC/Why-we-dont-sell-luxury-vinyl-tile#:~:text=PVC%20is%20made%20with%20large,the%20most%20hazardous%20pollutants%20known

- https://escholarship.org/content/qt85j5v7kz/qt85j5v7kz_noSplash_c1bfb194783a9ae9c375974b0c1a8899.pdf?t=smfsz5#:~:text=,However%2C%20the%20method%20used

- https://greensciencepolicy.org

- https://living-future.org/declare

- https://about.kaiserpermanente.org/community-health/building-healthy-communities

- https://healthybuilding.net

- https://www.copper.org

- https://www.nsf.org

- https://plasticpipe.org

- ASTM and ICC Codes – Material specifications for piping: ASTM F876, F877 (PEX); D1785 (PVC); B88 (copper); D2846 (CPVC)

- https://www.epa.gov/lca

- Used for quantitative carbon data per linear meter/kg:

- PEX EPD: Uponor, Rehau

- PVC/CPVC EPD: Charlotte Pipe, NIBCO

- Copper pipe EPD: CDA (Copper Development Association)

- https://spot.ul.com

- https://www.nsf.org

- https://www.ec3.eco

Other Categories:

- Roofing and Wall Membranes: Prefer TPO and EPDM over PVC (non-recyclable but less toxins on incineration)

- Baseboards and Trim– Rubber is base is preferred (recycled, similar carbon profile)

- Electrical Conduits: Steel EMT has high recycling rates and enhances fire-safety; fiberglass and HDPE fill the niche needs without the chloride problems

- Window shades and blinds: Fabric roller shades strike a good balance

References:

- https://www.buildinggreen.com/primer/buildinggreen-guide-pvc

- https://www.athenasmi.org/resources/lca-tools/

- https://roppe.com

- https://www.steel.org

- https://www.mechoshade.com / https://www.hunterdouglasarchitectural.com

- https://habitablefuture.org/wp-content/uploads/2024/04/Chlorinated_Pollutants.pdf